Specialty and Innovative Products

IRPC attaches importance to continuous research and development, especially self-development, to cater to its customers’ diverse needs and cope with economic volatility. The company has developed the following products to fulfill customers’ expectations while also taking care of the environment.

Green ABS

Green ABS is an innovative polymer conceived from IRPC’s corporate social and environmental responsibility awareness. The Company is the world’s first and only producer of green ABS, which is derived from natural rubber. Currently, 10-40% of synthetic rubber is replaced with natural rubber in the production of ABS, contributing to the increase in domestic rubber prices.

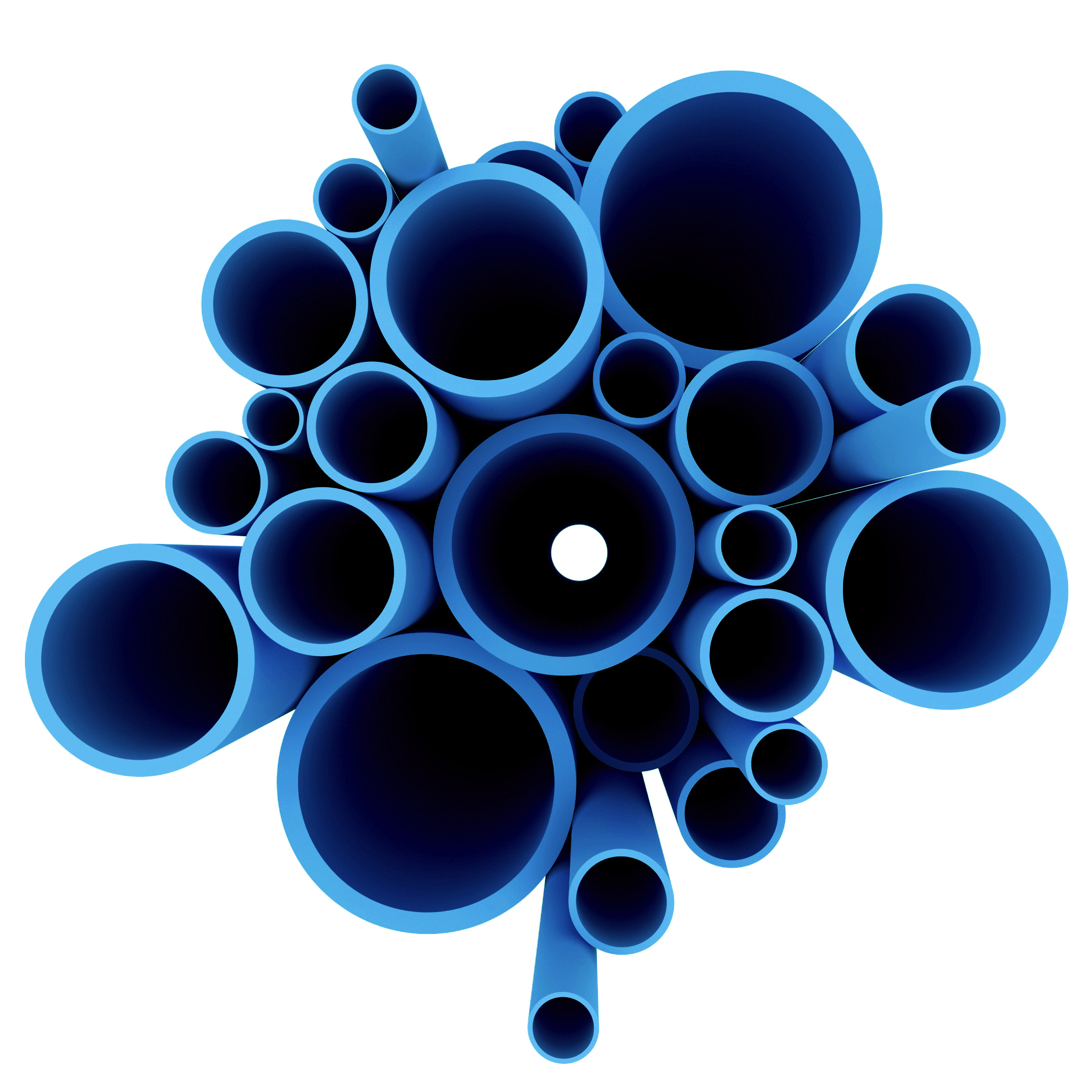

Chlorine Resistance Pipes

Chlorine Resistance Pipes are made from polymers that can withstand the corrosiveness of chlorine. These pipes are ideal as high-pressure drinking water conduits and have a longer lifespan than regular pipes, which lowers maintenance costs and ensures that drinking water would be free of contaminants resulting from corrosion.

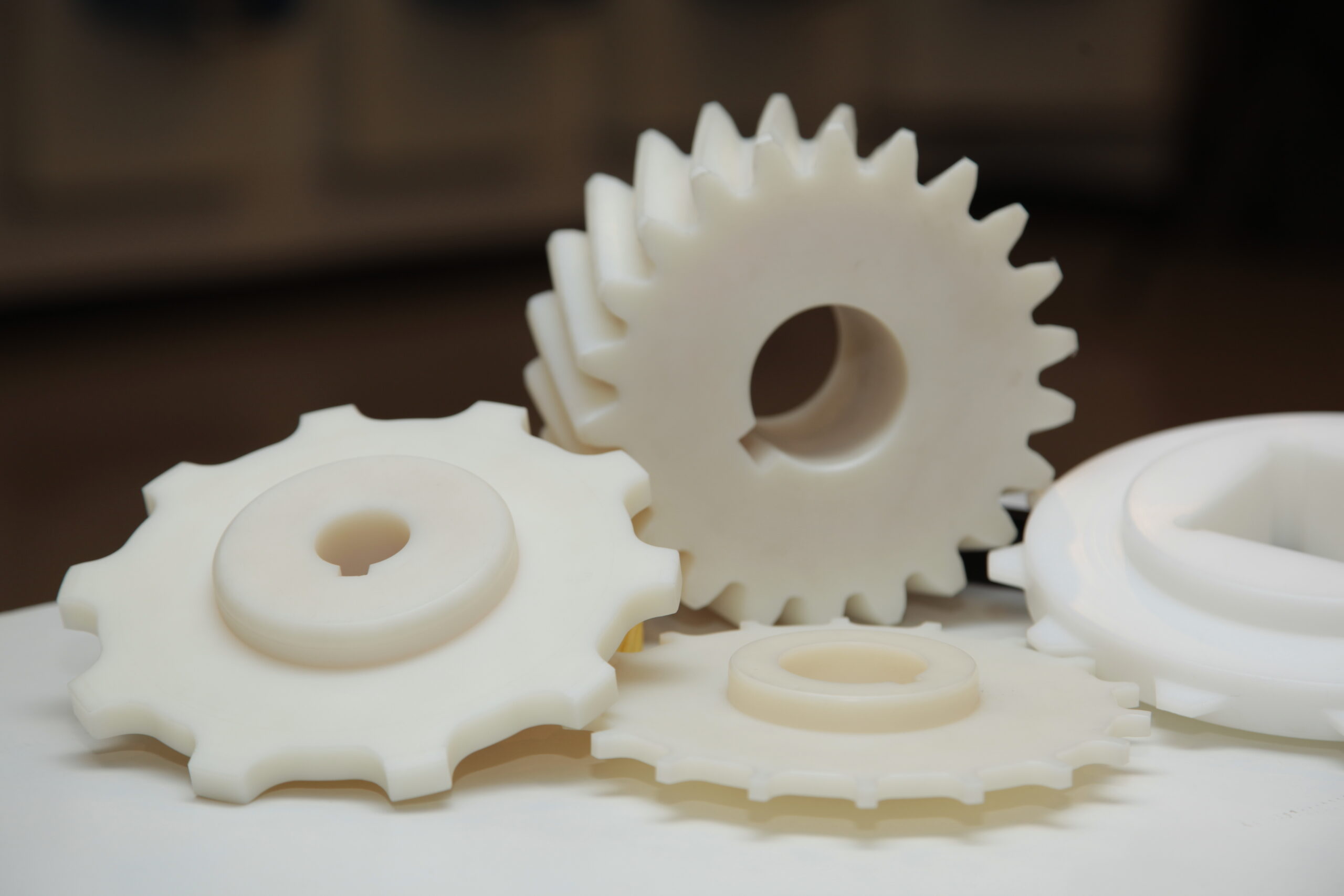

Ultra-High Molecular Weight Polyethylene (UHMW-PE)

Ultra-High Molecular Weight Polyethylene (UHMW-PE) is an opaque white powder with as much as 10 times higher molecular density than other PE varieties. It can be subject to a range of treatments, such as compression, RAM extrusion, and gel spinning. Thanks to superior properties to those of iron joints and gears, UHMW-PE is suitable for a range of applications that require toughness, strength, and resistance to abrasion and chemical erosion.

ABS Powder

ABS Powder is suited for manufacturers who require better polymer dispersion. It can be used alongside PVC, PC, and PC/ABS to augment their impact- and thermal-resistance.

Anti-dripping Additive

Anti-dripping Additive prevents polymer products from dripping when caught on fire. Made with nanotechnology, IRPC’s anti-dripping additive disperses well in polymers and can be stored at room temperature, which lowers storage and transportation costs. This agent can be added to a variety of polymers that need to meet the UL-94 (V.0) flame retardancy standard. IRPC has also used this anti-dripping additive to improve its flame- retardant ABS

Anti-bacteria Additive

Anti-bacteria Additive is another nanotechnology that prevents bacterial growth without adversely affecting the existing properties of plastics. It can be added to a variety of plastics, including ABS, PS, and PP.

Pim-L and Pim-AL

Pim-L and Pim-AL are special-grade acetylene black products that IRPC has developed in collaboration with NSTDA specifically for use as a carbon conductive additive in lithium-ion batteries.

Natural Color Compound

Natural Color Compound are colored polymers made from natural sources, such as green from spinach, brown from caramel, and yellow from turmeric. They overcome problems of toxicity and heavy metal residues. They also give the final product a more natural look and a long-lasting color lifespan.

Paralene

Paralene is a 20% bio-based polystyrene, effectively lowering the need for oil-based raw materials in the production process. It is FDA-approved and recyclable like regular polystyrene

Medical-Grade Polypropylene Random Co-polymer

Medical-Grade Polypropylene Random Co-polymer is a transparent PP developed specifically for medical equipment and related applications. It has been certified to various international standards, such as FDA US21 CFR 177.1520 of the United States of America as well as EU No. 10/2011 and European Pharmacopeia 3.1.6 and USP Class VI of the European Union.

Post-consumer Recycled compound

Post-consumer Recycled compound is made with used plastics that have been modified and thus has properties comparable to virgin plastic resins. Available both as PP and PS, this type of compound can help solve plastic waste problems and reduce environmental impact.

Live Stream

Live Stream